The glue will not cure if covered so after several hours remove the clamps and carefully remove the paper to leave as much filler as possible in the holes. Leave for a two to three hours to let the pressure distribute the materials and the glue will penetrate the existing chipboard.

The clamp should be snug to tight, you don’t need to crush the wood, just hold it tightly together. With a second wooden block on the other side tighten each clamp. Place smooth wooden blocks large enough to more than cover the hole over the paper. If your paper has a shiny side that side should face the glue. Place a piece of paper over each glue filled hole. I used screw clamps, you can use whatever you have available. Select pieces of scrap wood to protect your surfaces from the clamps which will dent, scratch, and break the surfaces of your drawers if they are not protected. Now we are going to apply some pressure with clamps. The glue will shrink as the moisture evaporates during curing so mound the holes full. You want to pack it as deep as you can into the bottom without leaving voids or bubbles. Working one hole at a time using the Popsicle stick or spreader, start pressing the filler into a hole. You want it on the wet side so the glue can bond to the chipboard in the next step. I keep adding glue or sawdust until the mixture is a putty like spreadable consistency. I start with glue, add sawdust which will absorb some of the moisture of the glue and mix. I used a plastic cup but it can be any container as long as it is clean. Start with glue in a disposable container. I mixed up a little at a time so I could get the consistency I wanted and so the batch wouldn’t get too gummy while working. Now it’s time to make our own chipboard filler and fill the holes. You want the sawdust pretty fine, no chunks or splinters so I sieved it. I grabbed a piece of scrap plywood, clamped it in the vice and started cutting from the end. If you use a pencil or erasable marker (dry erase, grease pencil) be careful not to erase your marks later when working in the area. It may be useful to look at other drawers to get an idea of what areas will be visible. If you use a permanent marker as I have take note which areas of the back of the drawer face will be visible when reassembled. I found using a long ruler lined up with the centers of pairs of holes horizontally, vertically, and diagonally to mark the area around each repair worked well. This step is important for getting the screw holes located later in the repair so the drawer front is aligned and spaced properly so take your time. Next, mark lines through the centers of the screw holes around each pit.

Alternatively you can gently clean them out with a brush with the holes facing downward. You can compressed air, or you can pucker up and blow them out with your own compressed air but be sure to close your eyes and wear eye protection, sawdust and debris is nearly guaranteed to blow right into your eyes with this method (voice of experience). Wearing eye protection, clean out the holes.

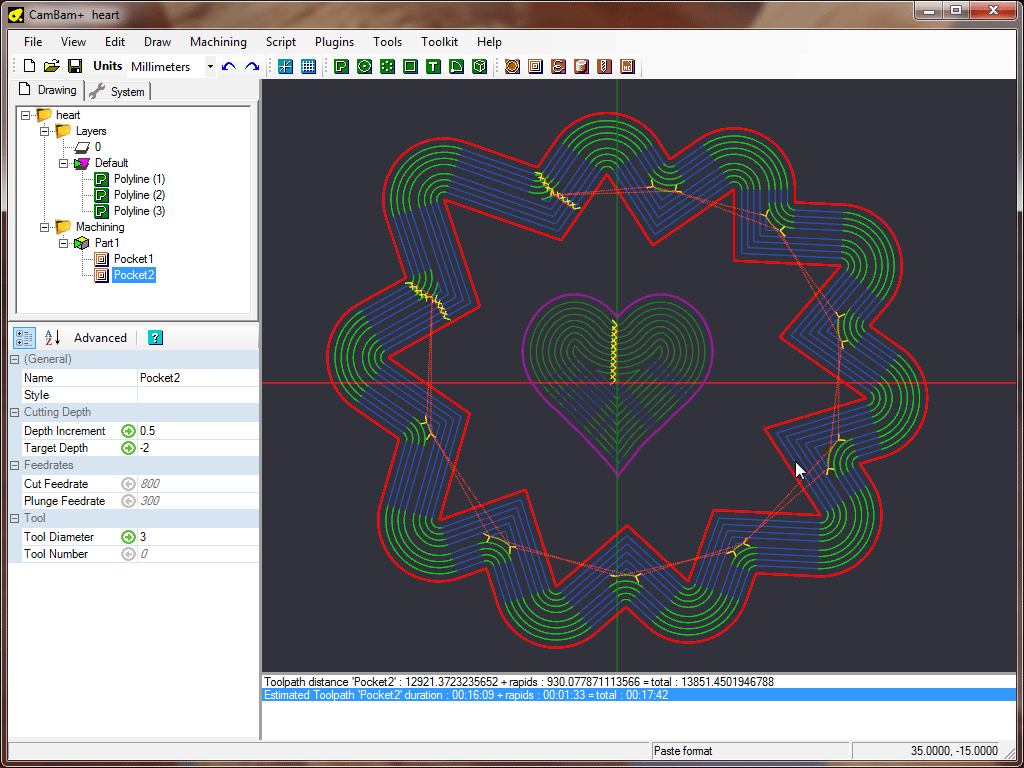

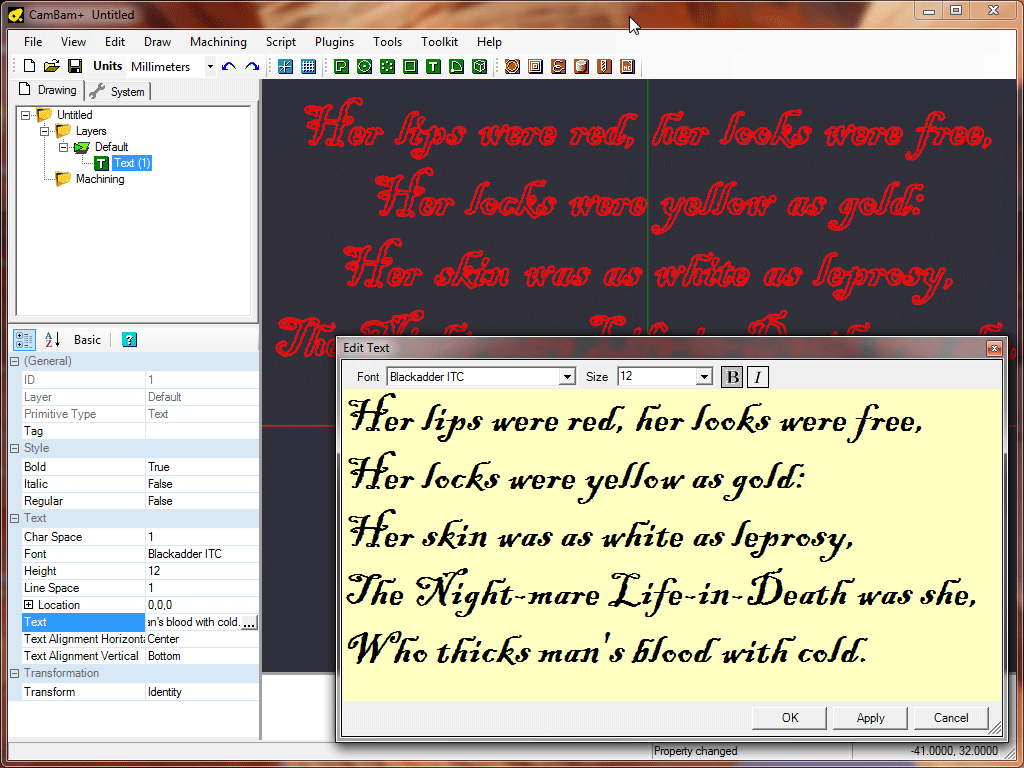

#Cambam used engrave to cut groove manuals

Last week I shut one of my shop drawers loaded with sandpaper and manuals with a too much “gusto” which ripped the drawer face off and left large deep pits in the chipboard around the mounting screws.

0 kommentar(er)

0 kommentar(er)